1. Connect the controller to the 220V voltage. If the indicator light is off, check the fuse position on the outside of the controller and the fuse is intact.

2. The controller is connected to 220 voltage, adjust the speed control rotary switch, whether to rotate in the specified direction, observe the speed of the vibration disk, slowly become faster, so that the vibration plate discharge rate reaches the customer's required speed is more than 20%, If the voltage is unstable, the vibrating plate will appear faster and slower.

3. The vibration plate can be placed at a time according to the size of the disk. If the workpiece in the vibration plate does not cover the chassis, it will be added immediately.

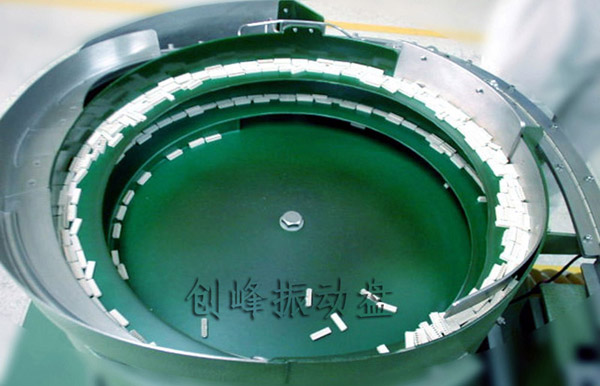

4. If the speed control rotary switch rotates to the end during the vibration plate work, the work still does not move. Please stop immediately to check if the chassis is faulty. If the chassis does not go, there are probably the following reasons:

1. The spring piece has a fracture phenomenon;

2. The bolts are loose;

3. The spring piece needs to be re-adjusted.

Solution:

1. Replace the spring piece;

2. Tighten the bolts;

3. Adjust the spring piece.

Note: For the method of adjusting the spring piece, select one of each group of spring pieces, loosen the bolt a little, and observe whether the speed of the vibration plate changes. If you need to change the spring piece to thin, you need to change the spring piece. Thickened, in this way can adjust the vibrating plate to the required speed

1. Automatic auxiliary material bucket, specially designed for saving and auxiliary materials, can automatically give vibration plate auxiliary materials, and the discharge of the vibration switch can be adjusted more or less.

2. Photoelectric switch, when the feeding track is full, it will automatically stop the vibrating plate, and the vibrating plate will start again when empty material. The empty and full material time will be illuminated by the factory indicator, which can save electricity and extend the use of the vibrating plate. life.

3. Feeding control switch, when it is sensed that the vibrating plate is not material, it will automatically let the auxiliary material bucket be fed to the vibrating plate.

4. Straight line feeder, can connect the distance between the vibrating plate and the machine track, so that the material is more smooth and difficult to jam.